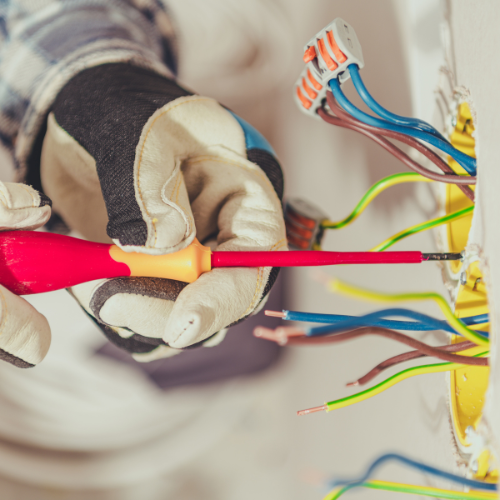

Most Trusted Residential Electrician

by Code One Electric LLC

When it comes to powering your home safely and efficiently, you need a trusted residential electrician who understands the importance of reliability, precision, and quality workmanship. At Code One Electric LLC, we provide comprehensive electrical services designed to keep your home’s electrical systems safe, efficient, and up to code. Whether you need a quick repair, a full wiring upgrade, or a new lighting installation, our licensed electricians are here to help.

With years of experience in residential electrical systems, Code One Electric LLC is committed to providing dependable service, honest pricing, and professional results for homeowners who expect the best.